Who we are…

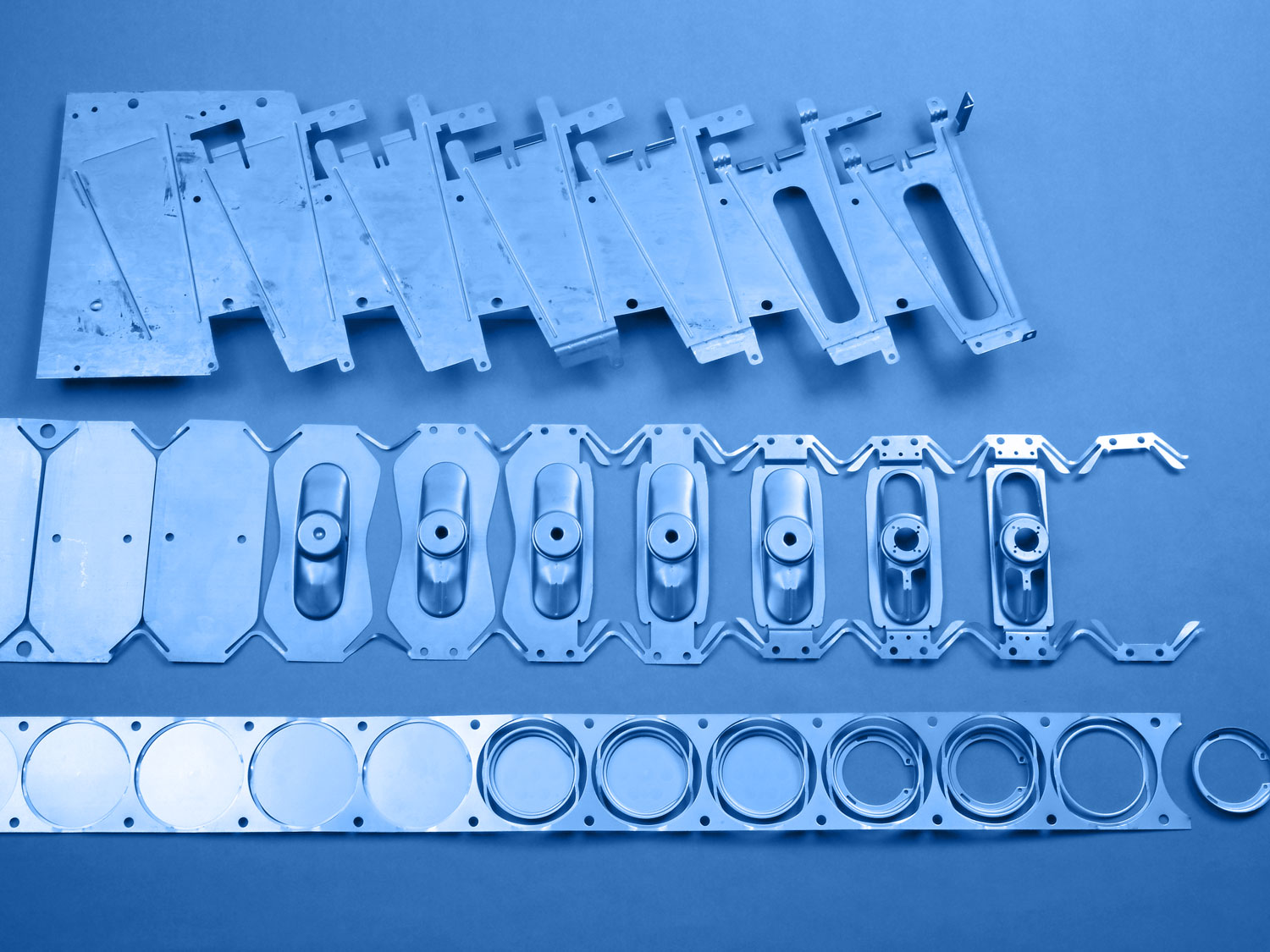

Culobel Group is an international technology partner with production facilities in Belgium and the Czech Republic and a sourcing office in China. We provide total solutions in sheet metal stamping, pressure vessels and assembly. Our constant innovation, a feel for creativity, and know-how built up over many years ensure outstanding quality. We assist you from the outset in the development of your product and possess the latest software with which to conduct feasibility studies.

Over 50 automated mechanical and hydraulic presses are testament to the state-of-the-art machinery we have in house.

Culobel has for a number of decades been a respected supplier of pressure vessels compliant with the most stringent EN standards.

Film

Quality assurance

In recent decades Culobel has put a great deal of effort into guaranteeing as effectively as possible the quality of the products it produces and the accompanying service it provides.

We currently hold the following certifications and approvals:

- ISO 9001: 2015: quality

- ISO 14001:2016: environment

- ISO 50001:2019: energy management

- ISO 3834-2:2005: welding

- 2014/68/EU Directive for CE products

Markets

During the course of our ample history and thanks to our many years of experience, we have been able to build solid partnerships with leading multinationals in different sectors:

- Cooling & Heating

- Pumping systems

- Hydraulics

- Compressors

- Domestic appliances

- The automotive industry