Sheet metal specialist since 1929

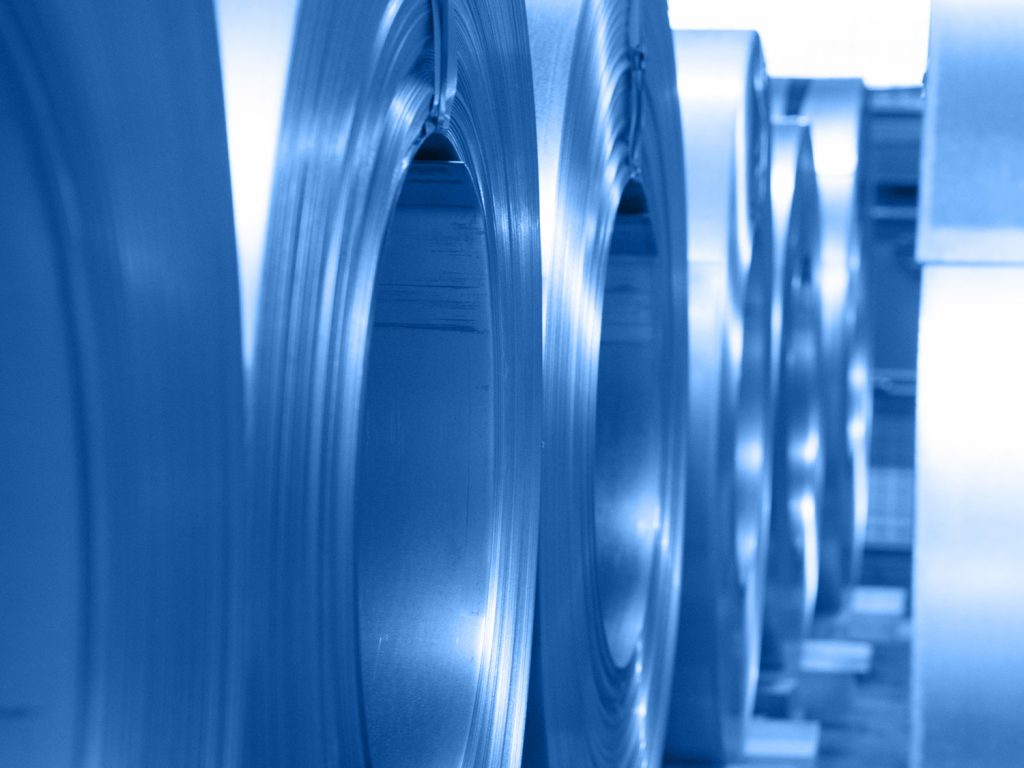

Culobel Group is an ISO9001:2015 certified sheet metal supplier with production units in the Czech Republic and Belgium. In our group we have more than 50 mechanical and hydraulic presses with a compressional force of up to 1,000 tons.

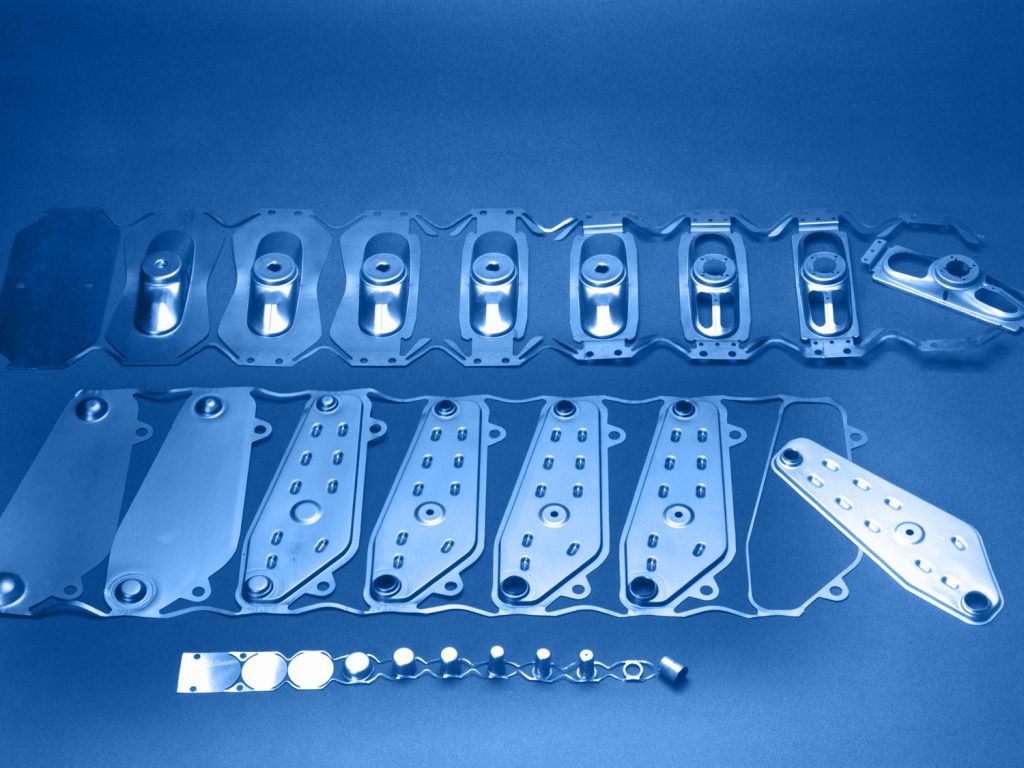

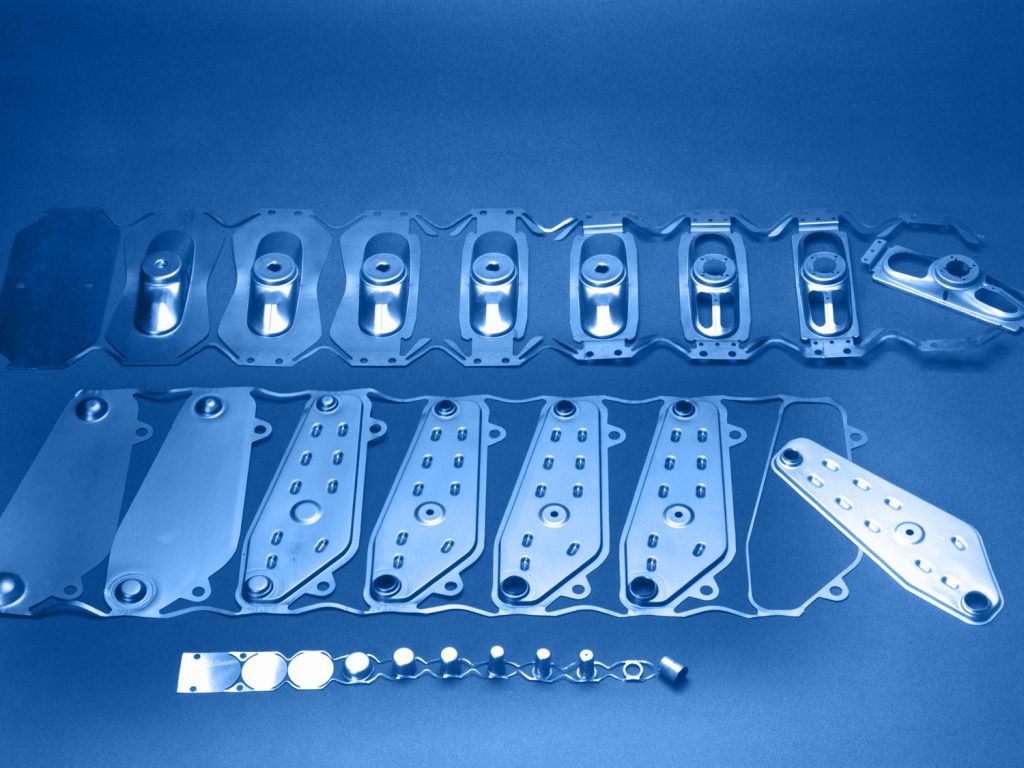

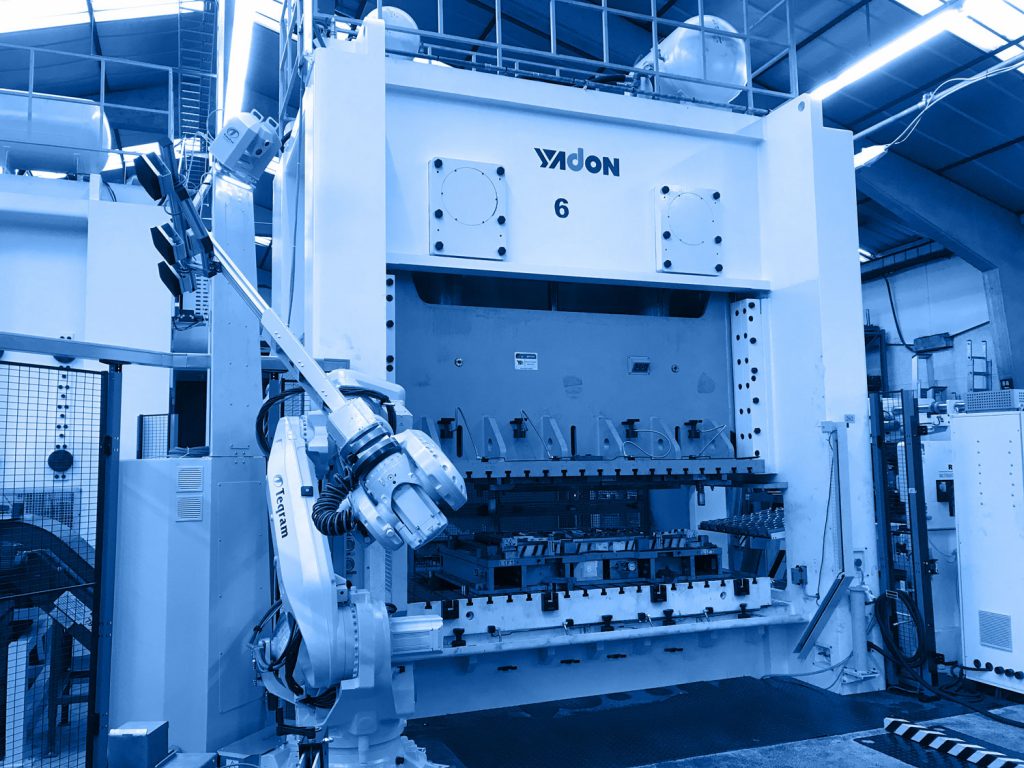

Our presses are equipped with automatic throughput systems, some of which are robot-supported. This automation enables an efficient pressing of all pieces. Progressive tools with a length of up to 3,000 mm and a tape input of up to 1,300 mm are one of our major assets.

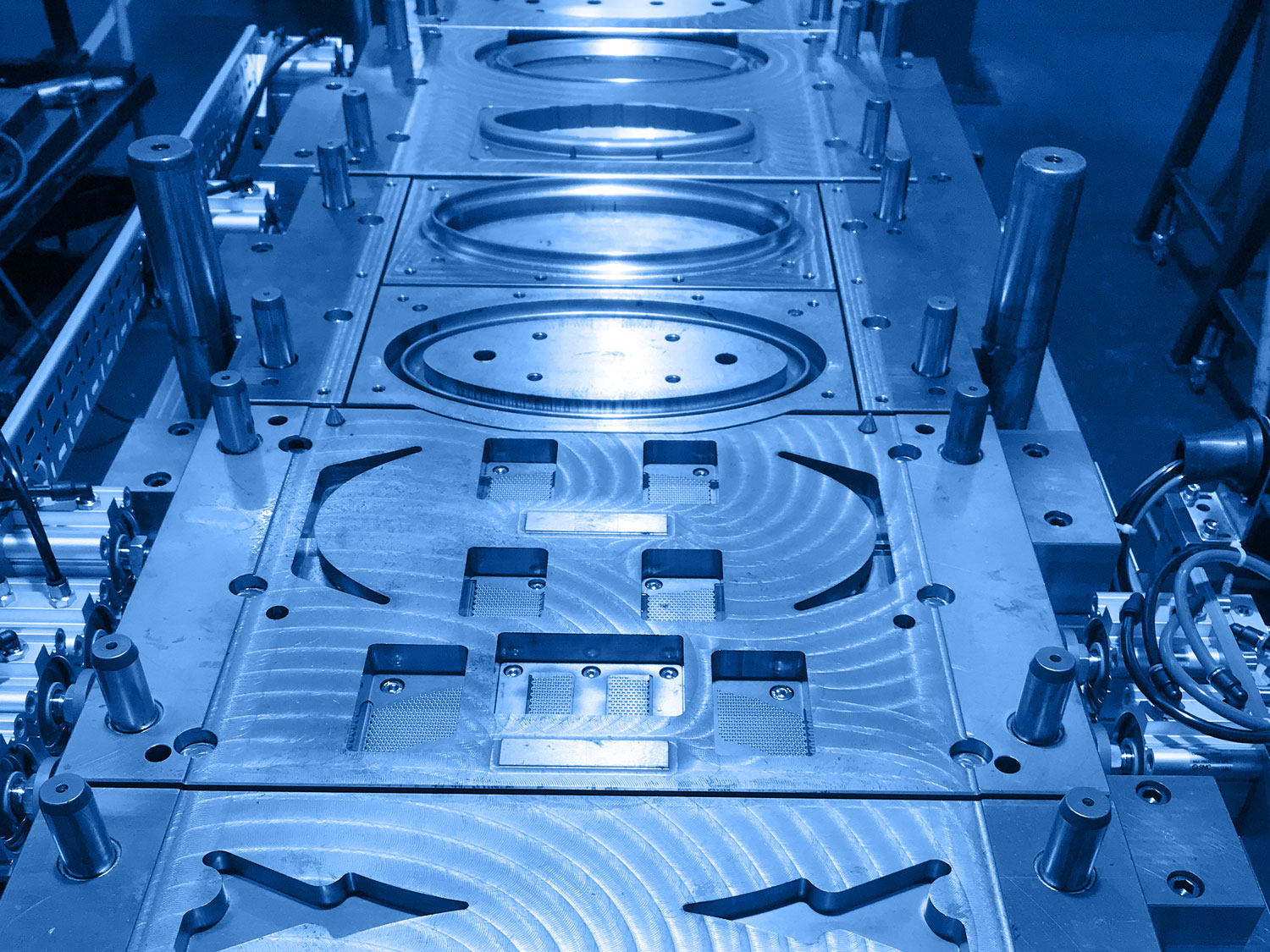

We have our own toolshop for die maintenance and adjustment. For new projects we enlist the services of our purchasing department in China which oversees locally the feasibility study for the pieces and construction of the corresponding dies.

From coil with a tape of up to 1,300mm

Stainless steel: Grade 304, 316L, 316 TI, 310, 321, 430, etc.

Steel: DC01-DC06; S235JRG2, QSTE380, DD11, DD13, etc.

Galvanised material : DX51DZ140 / 275 , DX53DZ140 / 275

High-alloyed steel : HX240 LAD, HX380 LAD, etc.

Aluminium: AL 99,5, ALMg3

Thicknesses

From 0.5 mm to 12 mm

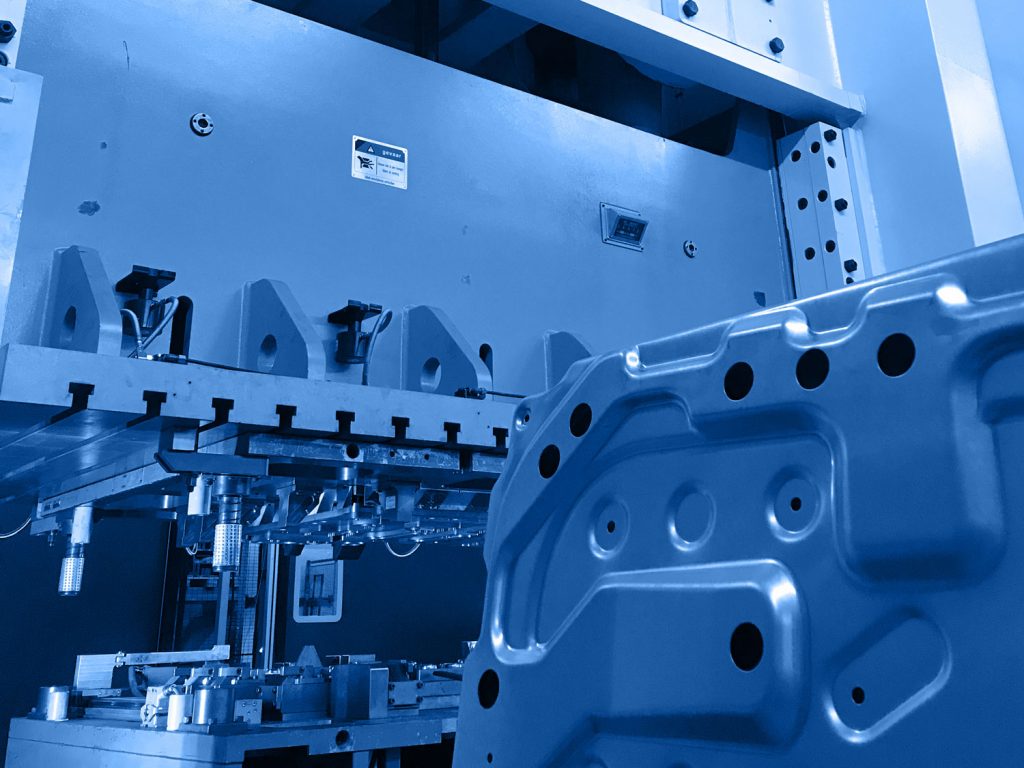

Automatic press line

Culobel Group is strongly committed to automation in order to meet present-day requirements and specifications. We have an automatic press line comprising three 630-ton mechanical presses, each fitted with a robot for the handling of large and heavy sheet-metal work.

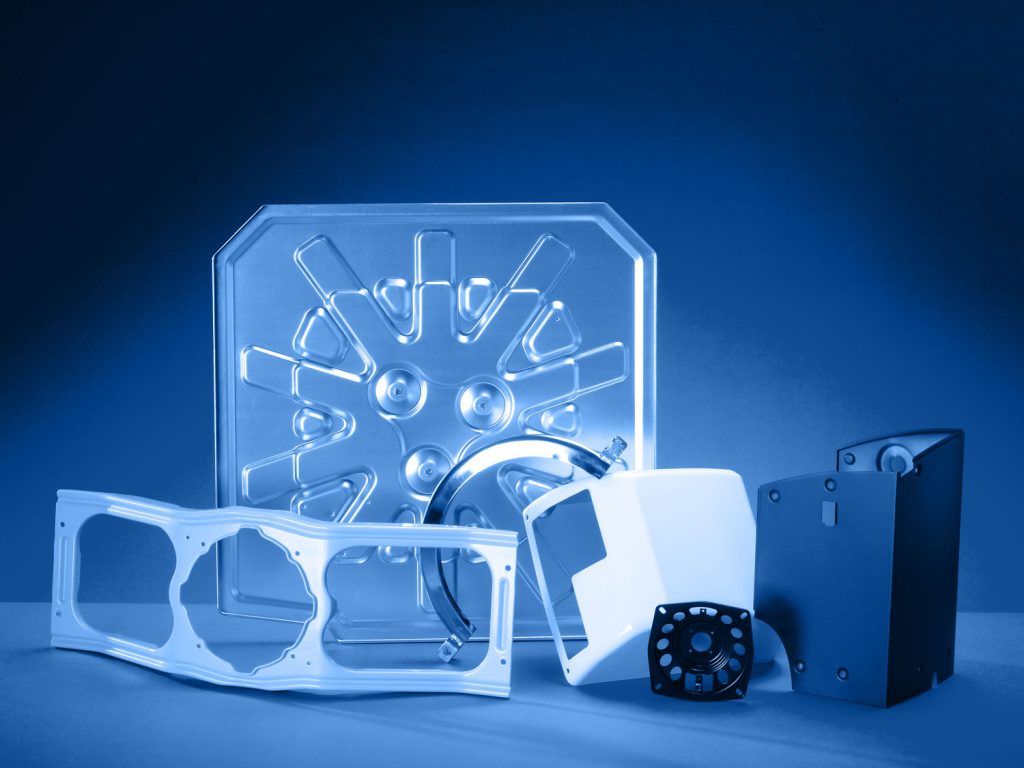

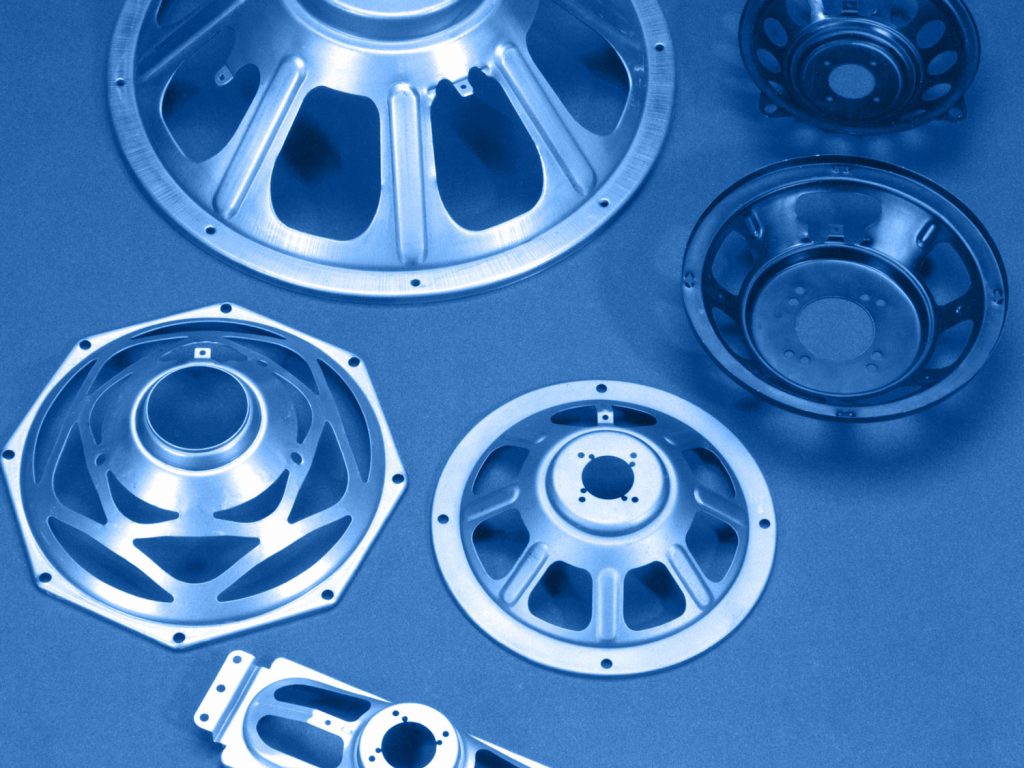

Deep drawing

One of Culobel’s absolute specialities is deep drawing work (an area in which we export far beyond Europe), since our hydraulic presses enable us to transform flat tape metal and discs of up to 10 mm in thickness in an automated fashion. The group’s showpiece is the 1,000-ton SMG press, which even makes thicknesses of up to 14 mm possible.

Machinery

- 1000-ton SMG

- 630-ton Yadon

- 600-ton Muller

- 400-ton LAUFFER

- 400-ton AP&T

- 2 x 400-ton Arisa

- 400-ton Müller Weingarten

- 3 x 400-ton Yadon

- 315-ton Erfurt

- 315-ton Yadon

- 250-ton Tranemo

- 3 x 250-ton Neff

- 250-ton Edelhoff

- 250-ton LDC

- 225-ton Müller Weingarten

- 200-ton L.V.D. MF TW

- 200-ton L.V.D.

- 200-ton IWK

- 200-ton Ching Fong

- 160-ton Müller Weingarten

- 160-ton Ching Fong

- 2 x 150-ton Richter

- 125-ton Bret

- 100-ton L.V.D.

- 100-ton Müller Weingarten

Design, toolshop & prototypes

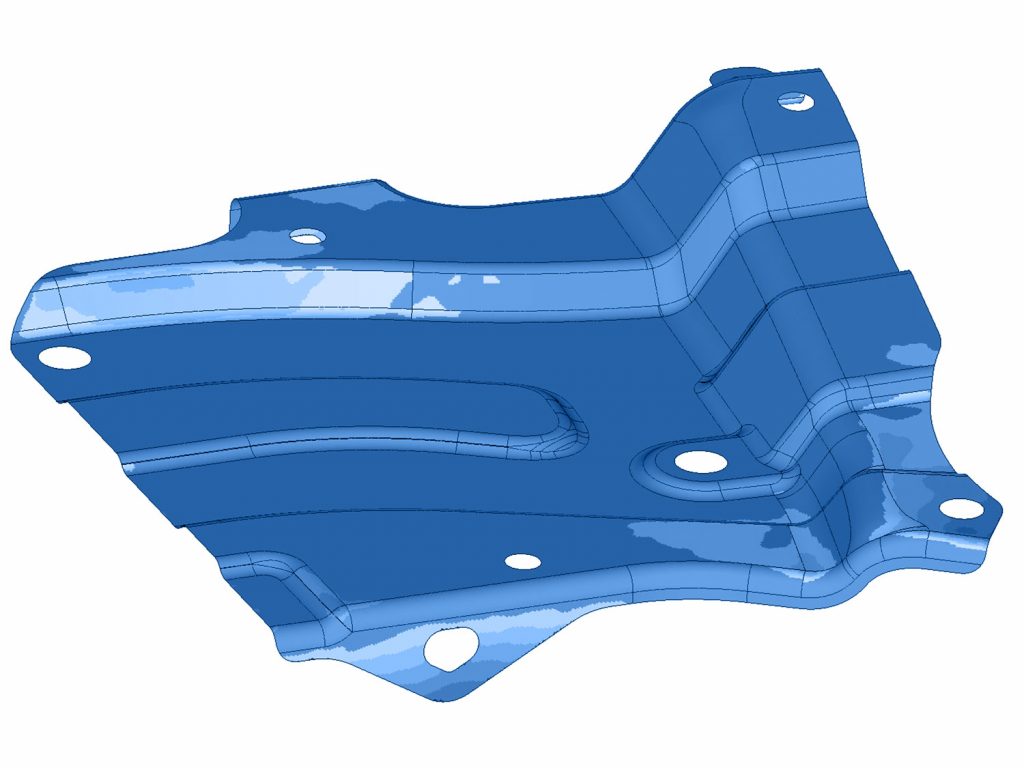

Our group has more than 90 years’ experience in the design, building and maintenance of dies. Our design department uses the very latest 3D rendering programs for support, as and when necessary, in the finalisation of your product. Our possibilities include feasibility studies, simulations & prototyping.

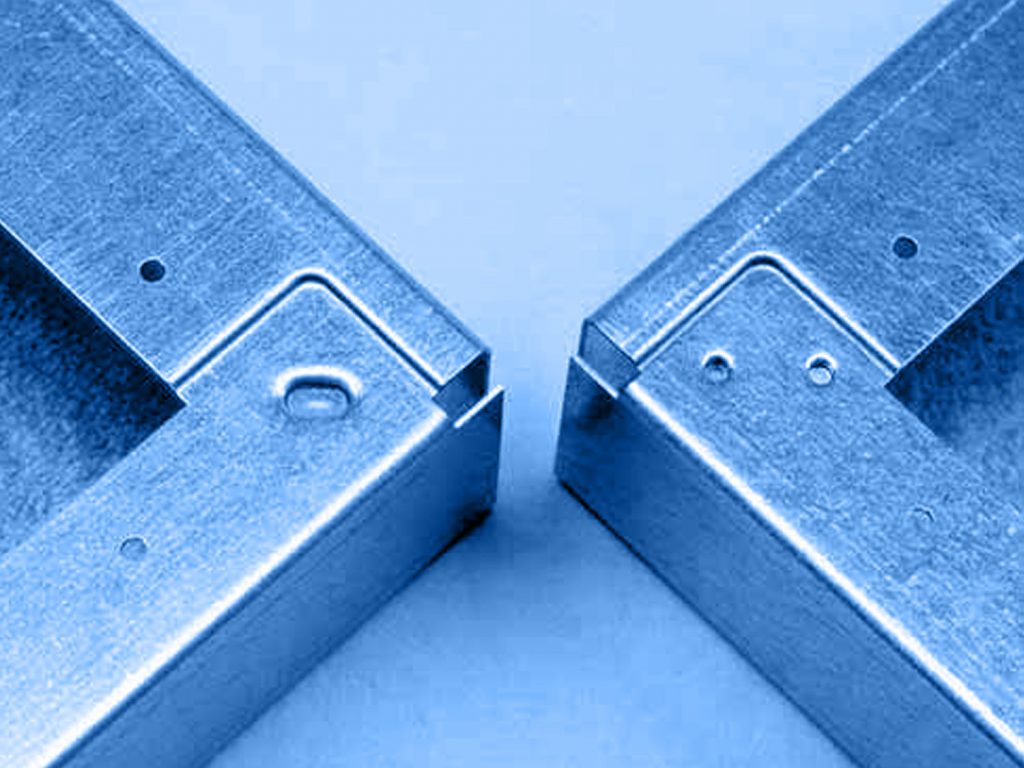

Backed by our many years of experience we are able to design complex progressive tools of up to 3,000 mm and integrate tapping and clinching in the progressive tool. We can therefore say with some pride that we manage more than 750 dies for our clients.

These days Culobel builds its dies in Europe and China via a select number of partners. Our toolshop in Belgium and the Czech Republic takes care of the further optimisation, testing and maintenance of the dies.

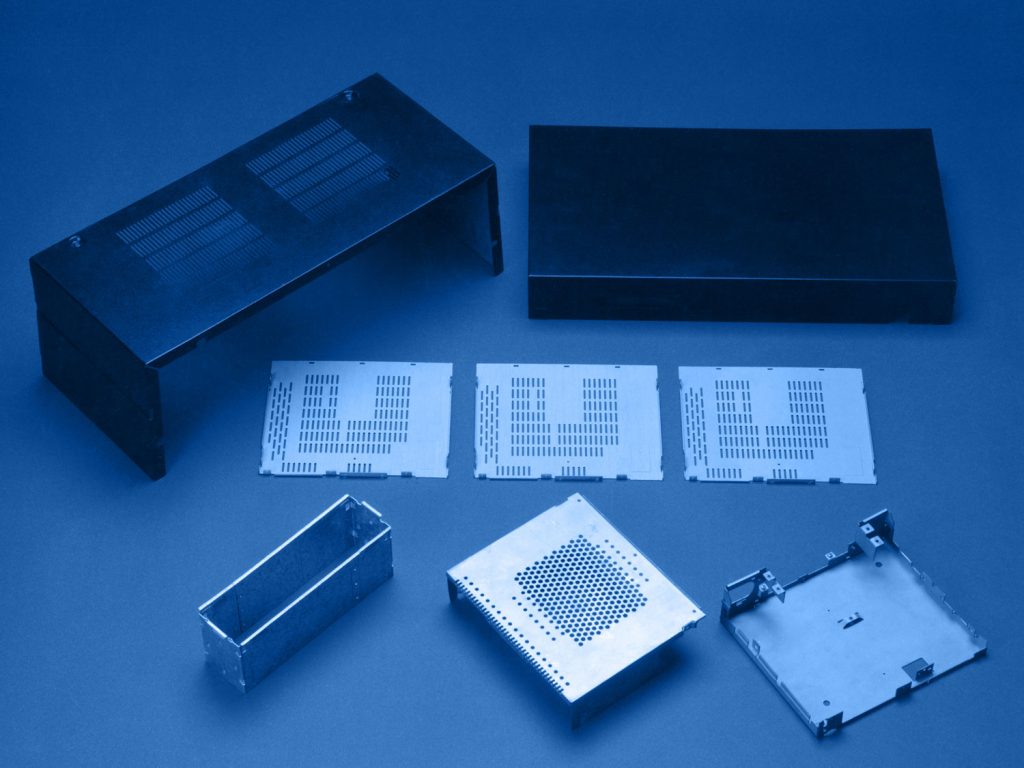

Sub-assembly

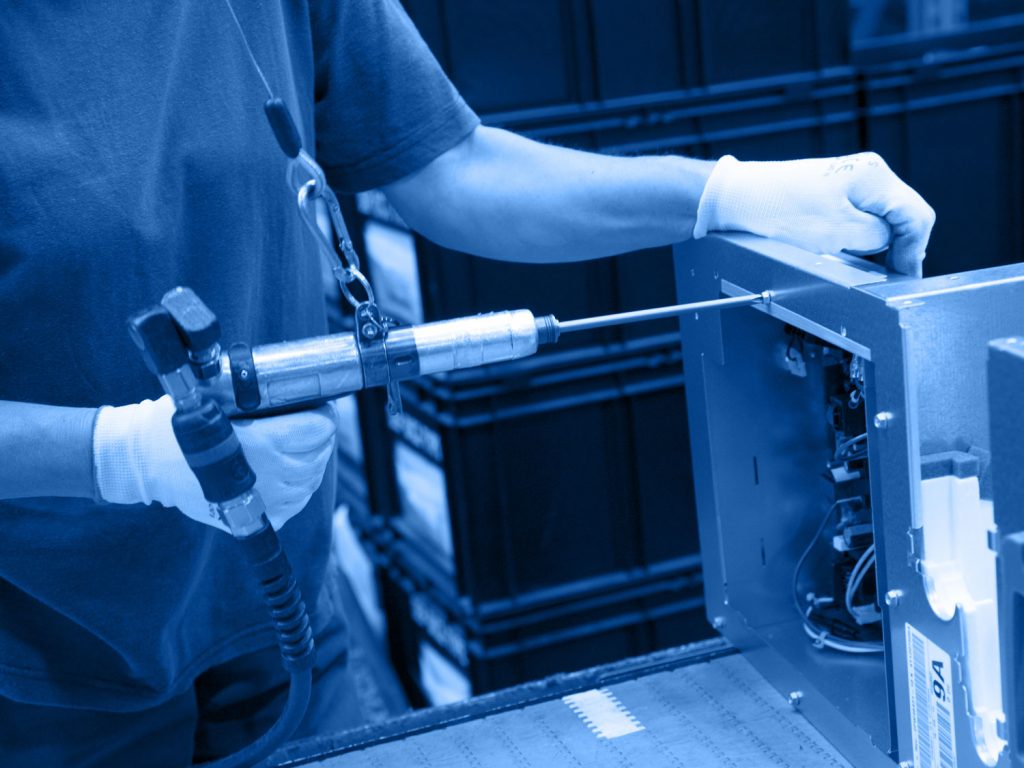

In addition to presswork Culobel Group also performs numerous (sub-)assembly activities for its customers:

- Spot welding

- Robotic MIG/TIG welding

- Clinching / TOX®-joining

- Stud & bolt assembly

- Screwing

- Assembly into the box

Powder coating

Culobel Group has had its own powder-coating line since the beginning of 2017, consisting of a spray tunnel (degreasing and phosphatising), a conveyor-belt drying kiln, a continuous powder-coating booth, a conveyor-belt muffle furnace and a chain-conveyor system that meet the highest standards.

References