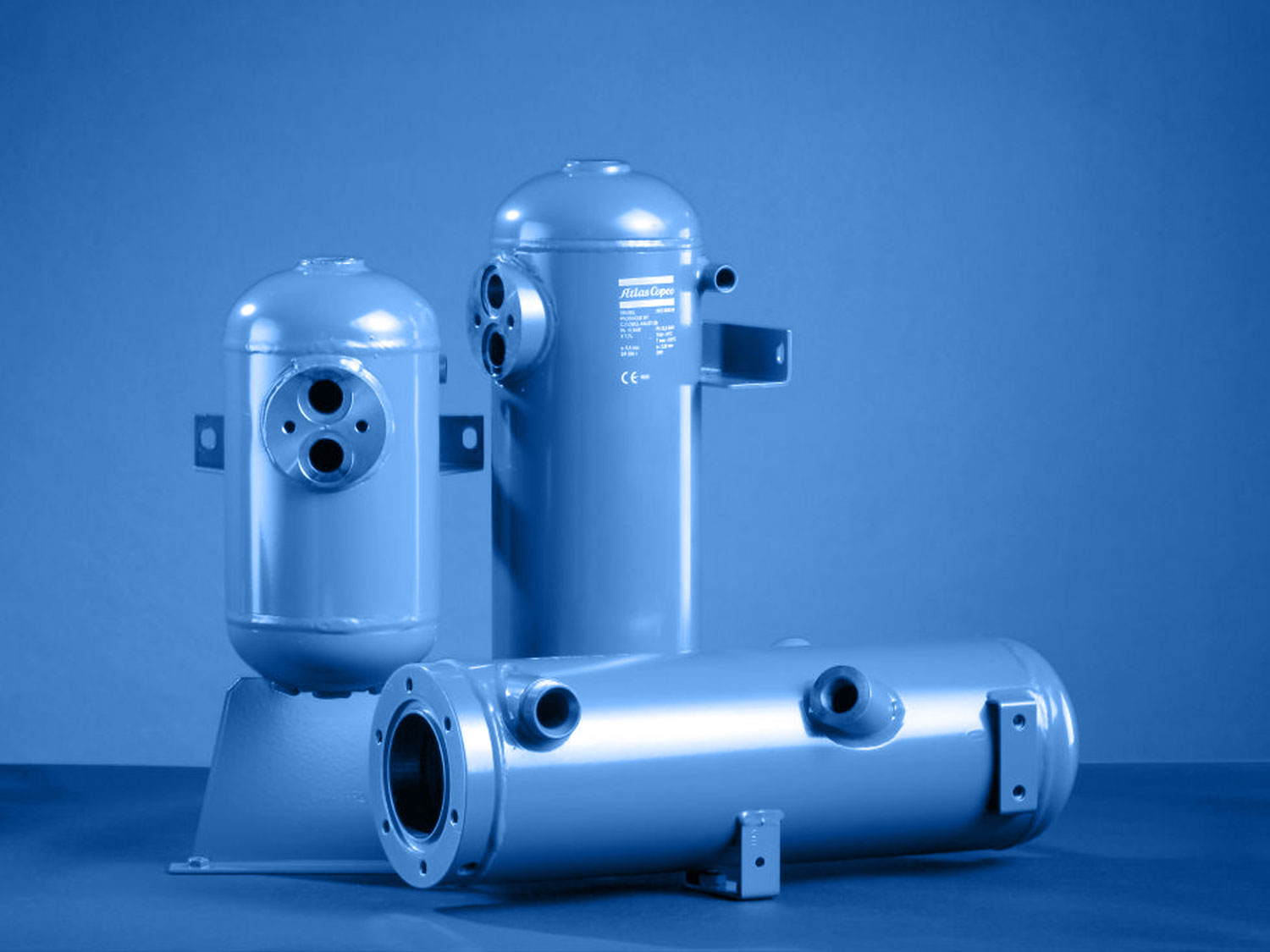

European reference for pressure vessels

The pressure vessels department is the fastest-growing division and produces pressure vessels tailored to the customer’s requirements for various uses.

Pressure vessels in small or large series from 0.75L to 200L pose no problem for Culobel.

Types of pressure vessels

- Accumulators

- Horizontal and vertical receivers

- Oil separators

- Pressure vessels for compressed-air systems / brake systems

- Mufflers

Characteristics

- Compliant with all PED, RoHS and REACH directives

- CE testing in accordance with PED directive 2014/68/EU – category II to IV

- Manual and robotic welding PED certified

- Induction soldering PED certified

- Working pressures up to 120 bar

- Testing pressures possible up to 300 bar

- Fluid group 1 (R32, R717 (NH3), etc.) and fluid group 2 (R410A, R134A, R744 (CO2), etc.)

- Non-destructive tests possible in accordance with EN14276-1 and EN 13445-5

- Internal moisture test

- Contamination test under 50 mgr/m²

- Degreasing and passivation by means of nanotechnology

- Powder-coating line PE 40 or PE50 RAL9005 sat (other colours possible on request)

- Coating thickness up to 100μm

- Salt haze value minimum 300h (1 layer)

Pre-treatment & powder-coating line

Since the beginning of 2017 Culobel Group has also had its own pre-treatment & powder-coating line. Our powder-coating line consists of a spray tunnel for degreasing and phosphatising, followed by a conveyor-belt drying kiln. In addition we also have a manual powder-coating booth for larger pressure vessels and/or prototypes.

CE-certified

All pressure vessels are CE tested and meet the most stringent regulations laid down by the Pressure Equipment Directive (PED 2014/68/EU). Culobel has all the necessary engineering expertise to develop new pressure vessels in accordance with EU legislation (PED) and using the best welding technology.

References